Just wondering, but is it possible for us to flip the leaf springs in our trucks? I have a friend with a Dodge 1500 that did it to his truck, and it doesn't look bad...

2,383 posts

·

Joined 2008

you need a flip kit, or a better option is hangers or shackles depending on how low you wanna go

2,586 posts

·

Joined 2009

I flipped my HD and am putting air ride in the back to help with the ride. You have to cut a notch out of the frame.

148 posts

·

Joined 2013

C Notch would be required, if you don't want to ride axle to frame. And a Kit is needed for the spring perches.

2,586 posts

·

Joined 2009

If it is not notched, the axle will hit the bottom of the frame causing a bad ride. It has to be notched to allow for suspension travel.

148 posts

·

Joined 2013

You said his is a dodge, not a Ford. So there's really no point in looking at his. You have to give the spring a perch to sit on. Otherwise the axle will twist around in the U bolts. You don't need a kit if you have skills, but either way you will need a welder.

14,724 posts

·

Joined 2005

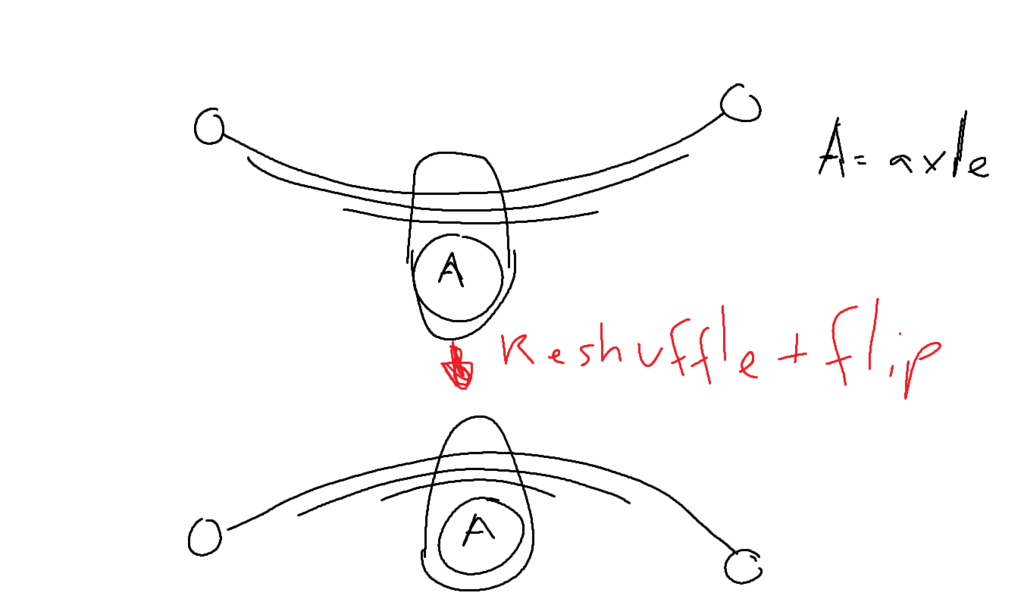

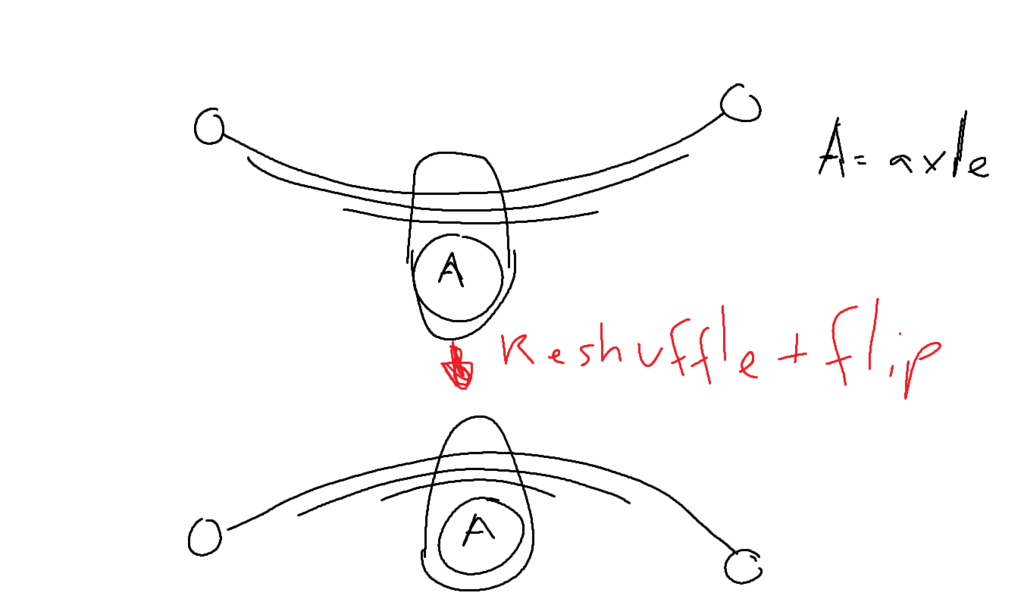

you guys are talking different types of flip.

the way it can be done is "flipping" the axle from the bottom of the leaf pack to sitting on top of the leaf pack. It can be done with longer U-bolts, and a perch, but you're going to bottom out without a c-notch and ride on frame rails.

the way I believe the OP is talking, from also reading his fb thread, is literally flipping the leafs upside down so they arch up instead of arch down. This way is not possible, and I don't even believe your dodge buddy did it this way, I think you're just misunderstanding him

the way it can be done is "flipping" the axle from the bottom of the leaf pack to sitting on top of the leaf pack. It can be done with longer U-bolts, and a perch, but you're going to bottom out without a c-notch and ride on frame rails.

the way I believe the OP is talking, from also reading his fb thread, is literally flipping the leafs upside down so they arch up instead of arch down. This way is not possible, and I don't even believe your dodge buddy did it this way, I think you're just misunderstanding him

Jeffv333

Discussion starter

2,238 posts

·

Joined 2014

Wow, thanks guys, yeah nothin but a whole bunch of uninformed people on FB but he'll I wanted to see how much information I could get from there, lol no help at all.

I need to look under his truck and take some pics and take some pics of my truck so I can clarify this. It's gotta be a complete different set up, but I agree it sounds impossible, which is why I asked this question...

Thanks to all who replied with actual inputs and logic, instead of the FB post nothin but smart allecs acting like they know everything. They thought this was a stupid question:scared003

I need to look under his truck and take some pics and take some pics of my truck so I can clarify this. It's gotta be a complete different set up, but I agree it sounds impossible, which is why I asked this question...

Thanks to all who replied with actual inputs and logic, instead of the FB post nothin but smart allecs acting like they know everything. They thought this was a stupid question:scared003

4,231 posts

·

Joined 2010

I still think you're confused. Spring packs don't work upside down. I've googled and not seen anything like what you're talking about on a Ram...

Jeffv333

Discussion starter

2,238 posts

·

Joined 2014

Dang, I am 100% sure my friend flipped those springs upside down lol and he might be damaging the rear suspension then, which is why I haven't done it to mine. I will inform him about that. I'll take pics of his when I see em. It's too confusing trying to explain this in words.

14,724 posts

·

Joined 2005

I still think it's a stupid question lol, but hey everybody needs to start learning from somewhere, so it deserves a real answer. FB is terrible for actually getting tech info or advice. It's good for sharing pics, and that's about it

2,586 posts

·

Joined 2009

Hear are a few pictures of mine. Common slang for this type of lowering kit is a "flip kit." I am sure that this is what you will find on your friend's truck.

Attachments

-

148.9 KB Views: 221

-

160.1 KB Views: 168

921 posts

·

Joined 2012

flipping the leafs up side down will level out the truck but will give you a hard and beyond stiff ride, you regret within a week and will switch back. a flip kit is what Mr. outsider posted which is putting the leafs under. you will have a good smooth ride using the actual flip kit just get the correct shocks for the amount the truck is being lowered.

12,893 posts

·

Joined 2007

Not a fan of flip kits, especially on high horsepower trucks. Do it right and get some drop leafs and shackles.

Jeffv333

Discussion starter

2,238 posts

·

Joined 2014

Found some very useful information here.

http://www.jalopyjournal.com/forum/threads/bad-idea-flipping-leaf-springs-on-a-rear-axle.465690/

So the best way to do this is to flip the springs and correct the order from top to bottom, flipping the springs as in the arch facing down instead of up(stock), and you can also lower it even more by putting it under the axle(requires welding in our trucks) and even a lot more of a drop by adding blocks in between the axle and the leaf spring flat bracket thing(welded). With this being said....a combination of all results in a major drop.

http://www.jalopyjournal.com/forum/threads/bad-idea-flipping-leaf-springs-on-a-rear-axle.465690/

So the best way to do this is to flip the springs and correct the order from top to bottom, flipping the springs as in the arch facing down instead of up(stock), and you can also lower it even more by putting it under the axle(requires welding in our trucks) and even a lot more of a drop by adding blocks in between the axle and the leaf spring flat bracket thing(welded). With this being said....a combination of all results in a major drop.

2,586 posts

·

Joined 2009

Did not have to weld with the kit I used. Also did not have to separate and organize the leaf s. Dropped the rear 5.25"

1,702 posts

·

Joined 2010

Ok reading your link, its all about 1950s& 60s cars, that already have the axle on top of the spring, I saw nothing relevant to our trucks

I'have to look, but didn't think the front hangers would accept the leafs flipped

I'have to look, but didn't think the front hangers would accept the leafs flipped

Jeffv333

Discussion starter

2,238 posts

·

Joined 2014

Yes true Outsider, but if you flip and reshuffle the springs it is a free drop, you had to pay for your "flip kit". Most people seem to say they don't recommend dropping your truck like this, and for most lightning owners I think would buy the kit since we have superchargers putting stress on the rear end lol

13,557 posts

·

Joined 2011

Hotchkiss leafs offer a 3" drop and ride like hell if thats what you want

Belltech hangers offer a 3" drop and acrew the pinion angle pretty bad if thats something youre willing to address

Hangers and shackels will get you 4-5" and youll need a cnotch. I bottom out occasionally with my belltech hangers, 1" shackle

but i know the follpwing contribute to it....hard bed cover, stock bumper, and tow package installed, spare removed.

Belltech hangers offer a 3" drop and acrew the pinion angle pretty bad if thats something youre willing to address

Hangers and shackels will get you 4-5" and youll need a cnotch. I bottom out occasionally with my belltech hangers, 1" shackle

but i know the follpwing contribute to it....hard bed cover, stock bumper, and tow package installed, spare removed.

Jeffv333

Discussion starter

2,238 posts

·

Joined 2014

Ok I will put a nail in this thread right now lol it is possible.:shitstormretarded

These methods used will make the rear a stiffer ride I would imagine. But the concept is the same as if force was pushing up or down on the spring.

If you take this bolt off....

Unbolt the U-Bolts from the axle to the springs. (ill come back to the highlighted green part later.

And unscrew the far off bolt at the front of the leaf spring.

If we take the whole leaf spring and flip it over, it will be a stiff ride but it IS possible to do and will lower the truck the least an inch and a half.

To get better suspension out of the springs some have suggested to shuffle the springs for better absorption of bumps. Either way shuffled or not will work but will result in a stiffer ride.

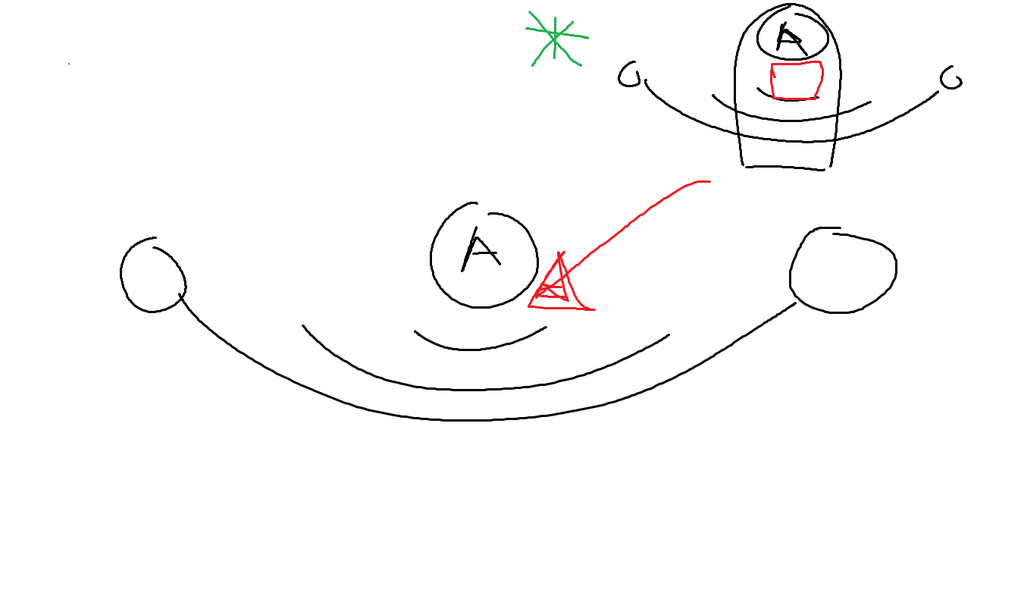

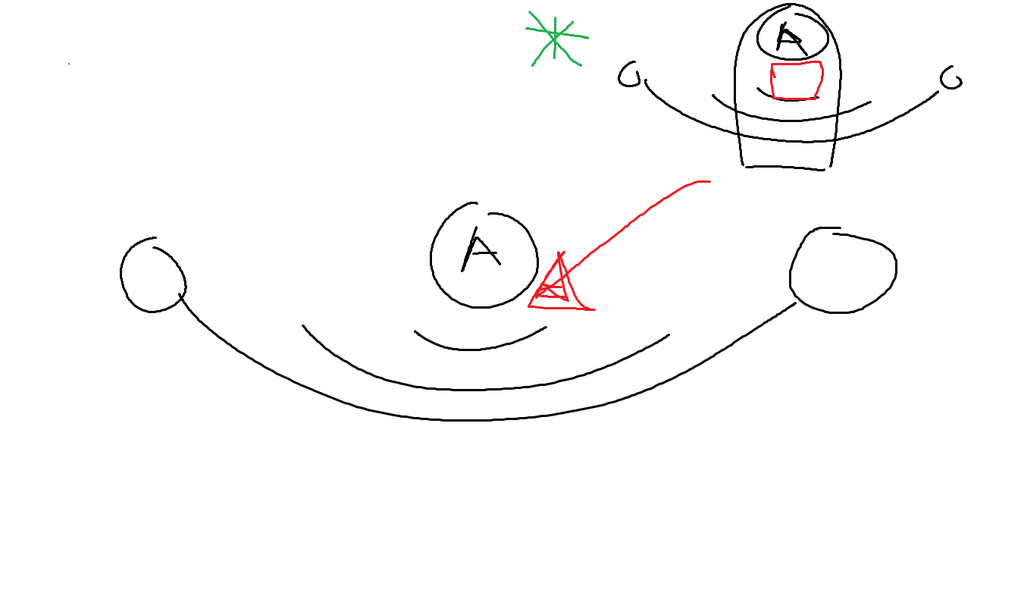

Now as far as if you would like to drop the truck more, welding would be required, if you take a look in the green arrow at the above picture #2 it shows the support for the leaf spring to sit on. You would have to weld a bottom piece to the axle to creat a support for your leaf spring if you want to transfer it under the axle like some suggested(which I never said anything about). Also you can lower it even more by adding blocks in between this way(see picture).

The result in all this is a free drop kit for yourself. Like me myself, I like to save money and would probably do this, but in the long run I don't know if it will damage my leaf springs which is why I asked if this was possible. But even then, I don't mind spending 50$ for shackles and take the safe route. Thank you everyone for your responses.

These methods used will make the rear a stiffer ride I would imagine. But the concept is the same as if force was pushing up or down on the spring.

If you take this bolt off....

Unbolt the U-Bolts from the axle to the springs. (ill come back to the highlighted green part later.

And unscrew the far off bolt at the front of the leaf spring.

If we take the whole leaf spring and flip it over, it will be a stiff ride but it IS possible to do and will lower the truck the least an inch and a half.

To get better suspension out of the springs some have suggested to shuffle the springs for better absorption of bumps. Either way shuffled or not will work but will result in a stiffer ride.

Now as far as if you would like to drop the truck more, welding would be required, if you take a look in the green arrow at the above picture #2 it shows the support for the leaf spring to sit on. You would have to weld a bottom piece to the axle to creat a support for your leaf spring if you want to transfer it under the axle like some suggested(which I never said anything about). Also you can lower it even more by adding blocks in between this way(see picture).

The result in all this is a free drop kit for yourself. Like me myself, I like to save money and would probably do this, but in the long run I don't know if it will damage my leaf springs which is why I asked if this was possible. But even then, I don't mind spending 50$ for shackles and take the safe route. Thank you everyone for your responses.

14,724 posts

·

Joined 2005

It is NOT possible. Yes in theory you could fip them around, but it flat out will not work on our trucks. You need to take into account the full suspension geometry, not just some 1950's ratrod forum where somebody made it work on their rat rod 39 coupe and assume it'll automatically work on our trucks.Ok I will put a nail in this thread right now lol it is possible.:shitstormretarded

If we take the whole leaf spring and flip it over, it will be a stiff ride but it IS possible to do and will lower the truck the least an inch and a half.

First off, an inch and a half drop? You're dreaming. It would probably be a full foot drop, if not more. It would almost put the axle ABOVE the frame rail. Our leafs have a significant arch to them stock. WHen you put weight on that arch, it flattens the leaf out closer to flat (just slightly arched). When you FLIP the leaf upside down, that arch is now going up, not down. And when you put weight on that flipped leaf, you're no longer trying to squish that arch flat when you put weight on it, you're trying to arch it even MORE.

See the attached pic to explain. I found a pic with a stock leaf and a drop leaf, but it's a good comparison for what it would look like compressed and uncompressed with the trucks weight on it.

The left pic would be stock setup. The lower leaf with the big arch would be uncompressed, truck in the air, rear dangling free. The upper leaf with the small arch, would be the compressed, the truck on the ground, weight on the rear.

The right pic would be the flipped setup. The upper leaf with the big arch would be the truck on the ground, weight on the rear, the spring trying to arch more under the weight of the truck. The lower leaf with the small arch would be uncompressed, truck in the air, rear dangling free.

So you can see you're not only gaining the difference in uncompressed heights on a drop (probably a foot+), you're also gaining the delta of height in compressed one direction vs. bowed in the other direction on the drop (probably another 6"+).

Attachments

-

145.3 KB Views: 225

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 2.5M

- members

- 30K

- Since

- 2004

Join our Lightning Rodder community to discuss the supercharged Ford F150 SVT and Harley Davidson edition pickup.

Explore Our Forums